Published in the May 2011 issue of “Die Porsche Kassette”

If you go online and check the different Porsche Forums (including mine, PedrosBoard.com) you’d think that these failures are a dime-a-dozen.

The truth is that a very small percentage of engines fail, but when someone has an engine failure the first place they go is on the Internet and post about their “self-destructing” engine.

You usually don’t read about someone who drove to work and back safely and his engine didn’t blow up that day!

So, should you worry about it?

I say no. Enjoy your car. Very few have catastrophic failures.

Having said that, let me try to quickly and simply explain what these potential failures are:

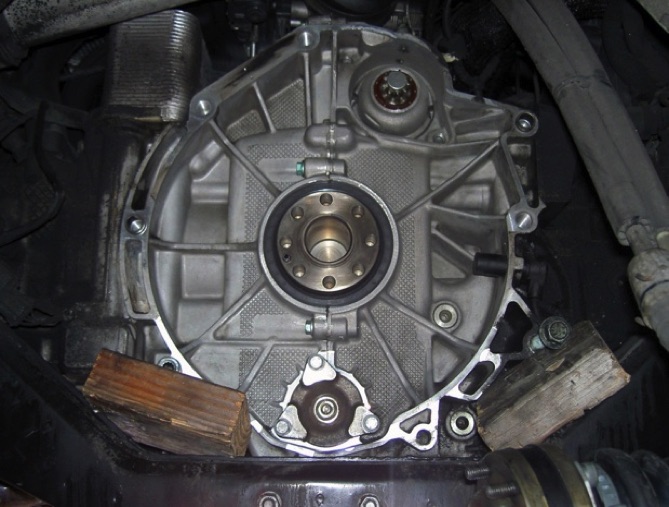

The one most people worry about is the Intermediate Shaft Bearing failure. Even though it’s referred to as the Intermediate Shaft (IMS) failure, what fails is the bearing at one end, not the Intermediate Shaft itself. All of the modern water-cooled Porsche engines up to 2008 have a shaft that runs the length of the underside of the engine block. This shaft is chain-driven from the crankshaft and in turn drives the double camshafts on each bank of cylinders. At one end of the IMS is a sprocket which spins on a bearing. The sprocket is held in place by a small stud that can break, causing the bearing to fail. The bearing can also show excessive wear because Porsche used sealed bearings which are lubricated “for life”.

These bearings eventually, with many miles and many, many heat cycles can tend to dry up the “lifetime” grease and because they are sealed and cannot self lubricate with oil, they can start to wear excessively . Eventually, if not attended to, the wear will allow the end of the IMS to move a bit which can alter the engine’s timing and catastrophic engine failure can happen.

If the engine goes, there is generally so much internal damage that it has to be replaced with either a new or a used engine ($8,000 - $18,000).

Is there a remedy?

Yes, there are several.

The easiest one is to replace the bearing before damage occurs.

This can be done in one of three ways:

1-Removing the engine from the car, dismantling it and opening the two engine block halves and replacing the bearing with either an OEM bearing or with an aftermarket one.

2-Replacing the bearing without engine removal with a popular aftermarket retrofit which uses a stronger, non-sealed bearing. This requires the use of a proprietary special tool for removal of the OEM and installation of the new retrofit.

3.- (*) Installing what we believe is the true solution to the problem, the Direct Oil Feed Kit which sends a stream of filtered, cooled oil right into the bearing’s innards therefore cooling and lubricating it’s surfaces. Our belief is that the IMS bearing failures have been caused by the lack of proper lubrication and cooling of the IMS bearing. Generally a new bearing with the outer seal removed is also installed when the DOF is put in.

All of these solutions are costly, much more so the first one, so my recommendation is that when you need your clutch replaced is the time to do the IMS retrofit since the transmission, clutch and flywheel have to be removed anyway. The IMS bearing sits behind the flywheel.

Some people have been able to catch the problem before complete engine failure occurs. Some have been lucky when replacing their clutch and caught it just in time while others were able to observe a foul-smelling oil leak that led them to replace the IMS bearing before engine failure happened.

Which cars are prone to this failure?

All of the M96/M97 Porsche engines have the IMS and thus are prone to have the bearing fail. These engines can be found in 1996-2008 Boxsters, 1999-2008 Carreras, and 2006-2008 Caymans. Turbos and GT3s have a different engine architecture and don’t suffer this malady.

We have also seen that tiptronic-fitted cars and cars that are driven hard, such as those that are tracked on a regular basis, are much less prone to the IMS bearing failure.

We have seen garage-queen cars that failed at 25,000 miles and tracked cars (mine) which were still running strong at 200,000+ miles.

Most of the catastrophic IMS failures come from 1999 - 2000 Carreras and 1997 - 2004 Boxsters but there have been a few from 997s and 987s as well.

Porsche has never admitted to having a problem with the IMS bearing on the M96/M97 engines. Nevertheless, they changed the design of the IMS no less than 4 times during the production life of the 996 and 986, they also reinforced the bearings on the IMS and evened out the stress on the shaft by re designing the cam chains and sprockets in later model years, especially when the M97 engine was introduced (on the 997s and 987s). Curiously, the latest engines (MA1) on 2009 and newer cars were completely redesigned to not have an intermediate shaft.

(*) In 2013 Porsche settled in a class action lawsuit brought against the manufacturer by a group of customers that had had IMS bearing failures. Porsche did not accept culpability.

We have also seen the “D-chunk” failure where the cylinder liner (generally in the center cylinder – No. 2 or No. 5 develops parallel cracks and eventually the bottom edge of the cracked cylinder releases a chunk in the form of a “D”. When these cracks develop, just as with the porous block engines, some coolant may mysteriously “disappear”.

Another one is the bottom-end failure due to oil starvation (on the track with sticky tires – because of the elevated G-forces that force the oil away from the pump’s intakes – this also happened to my ’98, but now with 203,000+ miles on the engine). What generally goes in these failures are the crankshaft bearings that overheat and break up due to lack of lubrication when the oil pump goes dry on the high lateral-force turns every lap.

One catastrophic engine failure that can be avoided easily by observation is the hydraulic-lock failure caused by a failed oil breather system also known as the Air / Oil separator (AOS).

This system is designed to distill oil from the crankcase vent and return the liquid oil back into the engine. When it fails, liquid oil can be drawn into the inlet system causing a hydraulic-locked engine and catastrophic failure. If your car starts smoking heavily on startups on a regular basis it’s generally a telltale sign of a bad AOS. A big cloud of smoke once in a blue moon is normal, but not constantly.

There had been a few other engine failures which are rarely seen anymore.

On the late model 1997 to early 1999 Boxsters there were the porous engine blocks.

Because the Boxster was such an unexpected sales success, Porsche had to quickly ramp up production and a few hundred porous blocks delivered to the assembly line from their contractor went undetected by their quality control procedures.

Cars with porous engines started filtering coolant into the oil through microscopic pores in the cylinders.

The engines that failed this way were generally replaced by Porsche at little to no cost to the owner (even when these cars were out of warranty – this happened to my ’98 at 27,000 miles when the warranty at the time only covered through 24,000 miles or 2 years).

Porsche was able to recall most of the porous blocks, but because of the production boom they tried to salvage the situation by boring the cylinders and pressing in a special sleeve into the cylinder thereby sealing the pores. The fix worked, but some of these engines had a slipped sleeve which required Porsche to also replace those engines as well.

Porsche has never disclosed the failure rates in the M96/M97 engines.

Some Internet figures have these failure rates as high as 20-25% of all engines, but from what I’ve seen in my own experience and also in discussions with many other independent Porsche techs who specialize in engine rebuilds, I’m a firm believer that the catastrophic engine failure rate in the aforementioned engines is only 1 - 2%.

That means that 98 -99% of the engines will lead long and healthy lives!

I think I’ll just go for a drive now.

(*) We now believe that the failure rates vary according to the model year and the way it is driven, or not. The lowest failure rates (1-3%) are the ’05 and newer cars with the larger, non-removable single-row IMS bearing. The ’97 – ’00 cars with the double-row bearing have failure rates of 4-7% and the ’00 – ’05 have the highest of al failure rates, just around 10%. These rates seem to climb when cars are not driven for extended periods and seem to decrease when cars are tracked regularly.

To find out more about our cars and their engines, please visit my website at: www.PedrosGarage.com.

(*) These paragraphs were added later to the article to bring it up-to-date.

The original article was written in December, 2010 and published in May, 2011.

Happy Porsche-ing,

© 2011 Technolab/PedrosGarage.com

(Rev. May, 2014)