Published in the August 2018 issue of “Die Porsche Kassette”

Ⓒ2018 Technolab / PedrosGarage.com

For more information on Porsches and more, please visit my website:

www PedrosGarage.com.

Happy Porsche'ing,

We all know that our beloved Porsche engines need air and gas to produce power, but how do the two come together since one comes from the outside and the other from the tank?

The first question is what year Porsche? And that’s because throughout the years there’s been continuous development in the way that gasoline is delivered to the engine and how it’s mixed with the incoming air.

The air delivery is pretty basic. Outside air is sucked into the intake box, passes through a filter to make sure that it’s clean, passes through the carburetor (early cars) or the throttle body (later cars) and then gets directed to the cylinders though the intake plenum manifolds. On naturally aspirated engines, the engine itself sucks in the air. On forced induction engines, the air is compressed or charged before it gets to the cylinders.

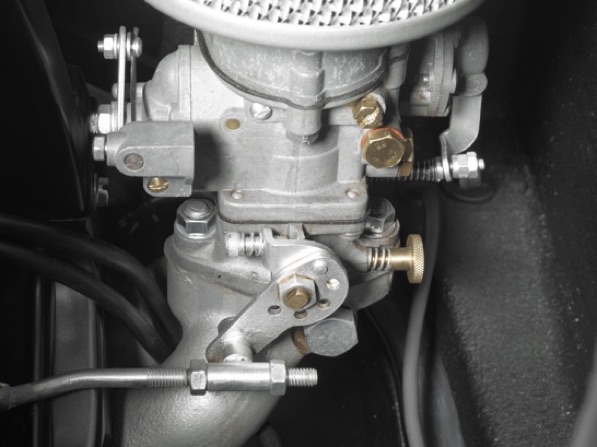

On the very first Porsches, 1948 – 1974*, air was pulled in, as described, and the carburetor would be responsible for providing the metered gas. Liquid gasoline does not ignite; only it’s vapors in the presence of oxygen, so carburetors use a set of jets to atomize the liquid gasoline in order for it to mix with the incoming air. These older engines used a completely mechanical system to try to obtain the optimal mix ratio (air - fuel) of 14.7:1 otherwise known as the stoichiometric point.

(*) Mechanical fuel injection was introduced for the first time in a Porsche in 1969, but it did not become standard until 1974, then evolving to digital management in 1984.

Carburetor

As more efficiency in the engines was required, mostly to make more HP for racecars, better ways of mixing air and gas were developed. The next step after the carburetor was fuel injection.

The earliest and most basic type of fuel injection is the single-point. It simply replaces the carburetor with a fuel injector nozzle in the throttle body which is where the air inlet (butterfly) valve is located. Though not as precise as the evolutions that followed, throttle body injection (TBI) meters fuel with much better control than the carburetor it replaced.

But in 1969 Porsche chose to use the newly developed Bosch Jetronic System, which injected fuel into a port just above each intake valve. This system was widely used until the mid 70s. The injectors were all interconnected by a pressurized fuel line known as the fuel rail and dispensed fuel by opening and closing at precise times throughout the engine’s cycle. Nominal fuel pressure in the rail is about 3.5 BAR or 50 psi. When more air was given by the driver when the accelerator was depressed, the Jetronic system answered by keeping the injectors open a bit longer by lengthening the pulse-width of the ground signal to the injector and thus obtaining the perfect mix (14.7:1). Typical fuel injector pulsewidths can be as little as 1.5 – 2.0 milliseconds (ms, or thousandths of a second) to over 20 ms at higher RPMs and loads. The positive terminals of the fuel injectors are always supplied with voltage, as long as the ignition is on. The switchable ground-path which completes the electrical circuit is controlled by a transistor in the electronic control unit (ECU).

Porsche has maintained their relationship with Bosch throughout the years and therefore has implemented most of their versions of fuel injection technologies, modified for the particular needs of the current Porsches at the time.

D-Jetronic was introduced in the four cylinder 914 because it was more than adequate for low-revving engines such as the VW Type IV used in the 914s which used a single throttle body and individual fuel injectors for each of the four cylinders. This system proved to be prone to mechanical wear and therefore inaccuracy in the mix so it was not used in the 6-cylinder 914s.

Fuel Injectors

The next version was the L-Jetronic which used a mechanical airflow meter for the first time to determine the amount of fuel metered into the cylinders. This version was applied to the 1.8L 914s (1974 – 1976 ).

Measuring the amount of air proved to be much more efficient that the previous arrangements and determined the direction of further development.

In 1983 Porsche used the Bosch Motronic System which integrated the electronic ignition timing control and the fuel control into a single control unit. From that point on, both Porsche and Bosch refer to this unit as the DME (digital motor electronics) instead of the ECU (engine control unit), although you may see it used indistinctly even today. The first offering of the DME came in the 944 with the 928 and 911 following closely behind in 1984. This system required very precise measurement of engine speed and position, so various engine component position sensors were introduced (crankshaft, camshaft and flywheel). On later versions, oxygen sensors were also integrated into Porsche’s Motronic Systems to obtain better catalytic converter function and to also correct excessive lean or rich conditions.

Many more developments were introduced into the Motronic Systems as time went by, such as onboard diagnostics (OBD), hot-wire mass airflow sensors (MAF) in the 32-valve 928, new onboard diagnostics (OBD-II) in model year 1996, additional oxygen sensors downstream of the cats, VarioCam technology (1997 Boxster and 1999 and Carrera), electronic throttle control (drive-by-wire in the 1999 Carrera and 2000 Boxster) but the fuel injectors remained basically unchanged for 40 years…

… until Direct Fuel Injection first appeared in a production Porsche in with the introduction of the new 9A1 engine of the 997.2 in model year 2009. As the name implies, fuel is injected directly into the combustion chamber, leaving just air being fed though the intake manifold. Injecting fuel directly into the cylinders (at pressures close to 2,000 psi) offers better homogeneity of the air-fuel mix.

Because DFI can inject the fuel closer to the source of ignition (spark plugs), it produces a more even explosion in the cylinders. The fuel mixture is therefore burnt more completely, increasing efficiency, reducing emissions and improving power.

But it’s not just benefits that DFI brings to modern cars. There have been a few issues.

Because of the extremely high fuel pressure needed to operate, fuel pumps have been not-so-reliable although getting better.

Another issue inherent to DFI is that because only air now flows through the intake valves, carbon deposits that were previously washed off by the gas-air mix now tend to create deposits on the valves.

It’s ironic that Porsche and other manufacturers introduced “new” DFI technology in 2009 when Mercedes Benz had used it and discontinued it in the 50s. My Dad’s 1954 MB300SL Gullwing and then 1958 MB300SL Cabriolet both had Bosch DFI and he was always complaining about carbon deposits in the intake valves.

Like the old saying: Old is new again!