Published in the December 2010 issue of “Die Porsche Kassette”

Have you ever had the Check Engine Light (CEL) come on in your car?

If it has, it’s actually the MIL (Malfunction Indicator Lamp) which lets you know that there’s a problem with the engine’s management system.

Whenever I’m servicing a Porsche and see the MIL on, it bothers me a little bit that the symbol is of a small block V8 and not of a beautiful flat-6 from a Porsche GT3.

The automotive monitoring system was developed by CARB (California Air Resource Board) and SAE (Society of Automotive Engineers) in an effort to reduce vehicle emissions, beginning in 1988.

It was called the OBD-I (On Board Diagnostic, generation 1).

The system, mandated by CARB, had to illuminate a “check engine” light to notify the driver that there was a potential failure in an emission’s component and the system also had to store a DTC (Diagnostic Trouble Code) in memory.

The regulations for OBD-I were very easy for manufacturers to comply with, since they were already monitoring most of these systems, but each manufacturer monitored in their own way.

Because of inconsistencies in the DTCs as well as in the data connectors from manufacturer to manufacturer and the inability of OBD-I to detect emissions system degradation, a new monitoring system went into effect in 1996, the OBD-II. It should have been in 1994, but it got delayed 2 years.

Below you can see the original Porsche OBD-I connector (round) which is found on the 964s and early 993s as well as on later 944s and 928s and on all of the 968s. The more trapezoid connector on the right, is the OBD-II found in all Porsches after model year 1996.

This newer version of On Board Diagnostics is much more sophisticated than it’s predecessor, and aside from doing all that the OBD-I did, it also added the ECM (Electronic Control Module) which controls the operation and performance of the vehicle’s subsystems. OBD-II now monitors:

ECT Sensor (Engine Coolant Temperature Sensor)

IAT Sensor (Intake Air Temperature Sensor)

IAC Valve (Idle Air Control Valve)

BARO Sensor (Barometric Pressure Sensor)

TP Sensor (Throttle Position Sensor)

ECM / PCM (Engine Control Module / Powertrain Control Module)

The specific ways in which the manufacturers had to comply was not specified by the regulations and each manufacturer made their own interpretations. For instance, the regulations state that a car has to monitor engine misfires, but doesn’t specify how, therefore some manufacturers look at O2 sensor waveforms, others look at crankshaft fluctuation and still others look at the current in the secondary ignition system.

Needless to say that OBD-II is a very complicated but very useful system which alerts the driver and the technician of possible engine malfunctions.

The OBD-II is capable of generating two different types of diagnostic codes:

“Generic” codes that are the same for all makes and models of vehicles (required by law) and ...

“OEM” codes that are unique to specific vehicle manufacturers.

The OEM codes cover non-emission related failures such as ABS, HVAC, Airbag, Electrical, etc.

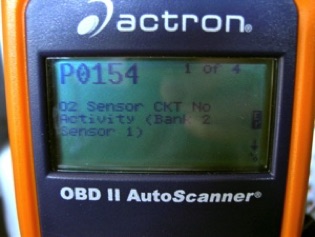

The generic codes can be can be read using a basic code reader or scan tool that is OBD-II compliant and usually cost less than $100 at any auto parts store. More and more car enthusiasts are adding an OBD-II code reader to their tool case to help them diagnose simple failures.

Because of the myriad of sensors and readings, a “Check Engine Light” or “Malfunction Indicator Light” can be triggered by something as simple as a loose gas or oil cap, since the system is also monitoring vacuum levels.

So an OBD-II scan tool can pay for itself if it helps you to discover something like this, saving you a trip to the repair shop.

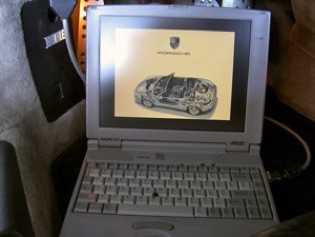

But, when the system failure is more complex, you will need to have a much more powerful tool that is capable of accessing all of the codes, as well as almost every component in the vehicle such as those found at the dealerships and independent repair facilities.

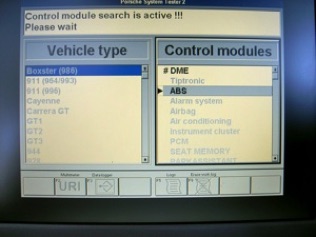

The one shown here, the PST-II (Porsche System Tester-II) was the second generation tester from Porsche, which recently introduced the PIWIS (Porsche Integrated Workshop Information System) as the latest in Porsche diagnostic tools.

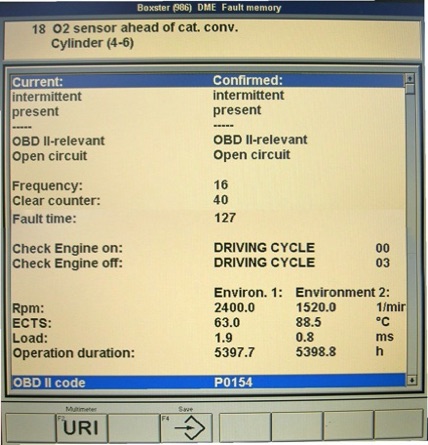

This screen on the PST-II corresponds to the same error code (P054) as shown above on the handheld scanner, but as you can see, there is much more information and accessible data on the specialized factory scanning system which help to find and correct failures much more quickly.

What the CEL should mean to you is:

If you see the CEL / MIL on, continuously, it’s telling you that the system found a malfunction in it’s monitoring. You should have the error code(s) read as soon as possible and perform corrective services.

If you see the CEL / MIL flashing it’s telling you that the engine is misfiring and damage to the engine is possible if it keeps running. Shut it off and contact a qualified tech or have it flat-bedded to a shop / dealership.

For additional information on diagnostics and code errors, please visit our website at: www.PedrosGarage.com.

Happy Porsche-ing,

© 2011 Technolab/PedrosGarage.com