Published in the September 2011 issue of “Die Porsche Kassette”

Once upon a time you could only use Porsche coolant in your water-cooled Porsche, but times and products have changed and now you have a choice ... several, actually.

I know you’ve heard the stories about how your coolant will turn to gel if you put something else in there other than genuine Porsche coolant, but if you have a little patience and read on, I’ll give you the skinny. For those of you with “real” air cooled Porsches, thank you for reading this far, but you’ve read enough. See you next issue ;)

Logically, you’d think that a “wasserboxer” engine (water cooled boxer engine) would be cooled with wasser (water) right? Not exactly. And why does it need to be water cooled, anyway?

A typical, 6 cylinder Porsche cruising at around 70 mph (3,350 RPM) will produce 10,050 controlled explosions per minute inside the engine, as the spark plugs ignite the fuel/air mixture in each cylinder. Obviously, these explosions produce an enormous amount of heat, and if not controlled, will destroy the engine in a matter of minutes. Historically there have been 2 choices for controlling this heat: air and water cooling. The original Porsche engines were all air-cooled, but with the advent of more strict environmental regulations it became more efficient to use water instead of air to cool the engines and now all internal-combustion engines in Porsches are water cooled.

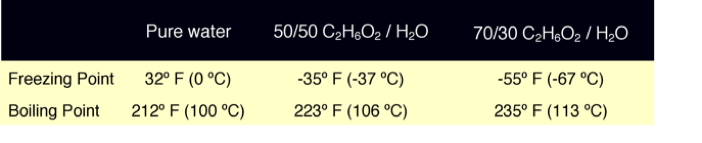

Pure water is probably the best fluid for holding and transferring heat, but it has three problems. It freezes at 32º F which causes it to become solid and expand, thus cracking the engine, it boils at 212º F turning into vapor at too low a temperature considering those generated by the internal combustion engine, and pure water running through the cooling system would promote internal galvanic corrosion.

So, science came to the rescue. By adding a chemical product known as Ethylene Glycol (C2H6O2) to pure water, it changes the freezing and boiling points of the new fluid, now known as antifreeze or coolant.

Adding Ethylene Glycol obtained the needed anti-freezing qualities, but the coolant still boiled at too low a temperature. So again, science to the rescue. By pressurizing the system to a safe pressure of 14.7 psi the boiling temperature of the coolant is now raised another 45º F (25º C) so the coolant can withstand the higher temperatures without boiling.

Coolant or antifreeze, has four (4) basic functions it must provide:

1.- It must carry heat from the engine to the radiators where it will be dissipated

2.- It must not freeze in the winter and must not boil in high temp environments

3.- It must lubricate the system’s moving parts such as the water pump, and

4.- It must protect the cooling system against corrosion

There are 3 basic types of coolants based on the different types of additives used:

Inorganic Additive Technology (IAT), Organic Additive Technology (OAT) and Hybrid Organic Additive Technology (HOAT). Although, technically each one of these would work on any automotive cooling system, each one was developed to meet specific manufacturer’s needs.

IAT has been around since the first water cooled engines. It contains silicates and or phosphates that form a protective barrier on everything in the cooling system, even on the hoses. IAT coolant is generally recommended for iron-block and heavy-duty engines.

OAT coolants work differently. Aluminum and ferrous metals form a surface-layer of corrosion in the presence of moisture. OAT coolants anneal (transform by the engine’s heating and cooling cycles) this metal-oxide layer into a thin surface coating that protects against further corrosion. OAT coolant is what’s in our engines because most of the components are aluminum.

HOAT are hybrid coolants that use both silicate and organic acid corrosion inhibitors, generally recommended for engines that have iron-blocks and aluminum heads.

The recommended antifreeze for our Porsche vehicles is the OAT type.

Many of the famous, over-the-counter brands offer OAT coolant with an aluminum-protecting inhibitor package and contain no silicates, borates or phosphates and will be stated as such on their labels. Generally these are called “Extended Life Antifreeze Coolant”.

These coolants can be put on top of the existing Porsche coolant, if needed for a top off, even if it’s a different color, and although Porsche sells it’s coolant as a lifetime product, whenever there’s a need to service any cooling system component, such as a radiator, a cooling line, the thermostat or the water pump, for which the system must be drained, fresh coolant mix should be used to ensure that the additives are there in the necessary quantities to protect the newly installed surfaces.

As we saw in the table (above) the recommended mix for most of us in the lower 48 is a 50/50 mix of antifreeze and water. Because tap water contains many minerals and chemicals which could reduce or eliminate the wanted effects of the additives, it is highly recommended that distilled water be used for the dilution. You can purchase an already diluted 50/50 mix from most of the antifreeze manufacturers, but it is generally cheaper if you make the mix yourself and you can also adjust the proportion to your specific needs.

Check you coolant level frequently. If you notice a drop in level (from cold to cold) check your coolant cap. Chances are it’s an old (even an original) cap which needs to be replaced after 4 or 5 years, since it can lose it’s pressure-holding ability. If you need to top off, it’s fine to do it with just distilled water. You don’t need to use mix, not for a small amount.

The Ethylene Glycol used in coolant is poisonous to humans and pets. Take all necessary precautions.

On a final note, regarding the “mixing of non Porsche coolant with Porsche coolant will turn to gel” issue, here’s the scoop.

Porsche was one of the first manufacturers to use an all aluminum engine and they were pioneers in the development of the Organic Additive Technology (OAT) for antifreeze. In those days the concentration of silicates, borates and phosphates (among others) was so high in the commercially available IAT coolants, that when mixed with OAT this would cause the additives to precipitate out of solution and would clog many of the fine cooling vanes in the radiators and engine. This precipitate had the consistency of slush.

Bottom line: Don’t mix different types of antifreeze.

To obtain additional information about antifreeze / coolant, cooling systems and more, please visit my website at: www.PedrosGarage.com.

Happy Porsche-ing,

© 2011 Technolab/PedrosGarage.com